Textek is the UK’s most advanced Bulk Waste Processing Site.

They said it couldn’t be done!

Many companies have tried to develop an automated solution for recycling mattresses and bulky waste, but up to now… none had succeeded.

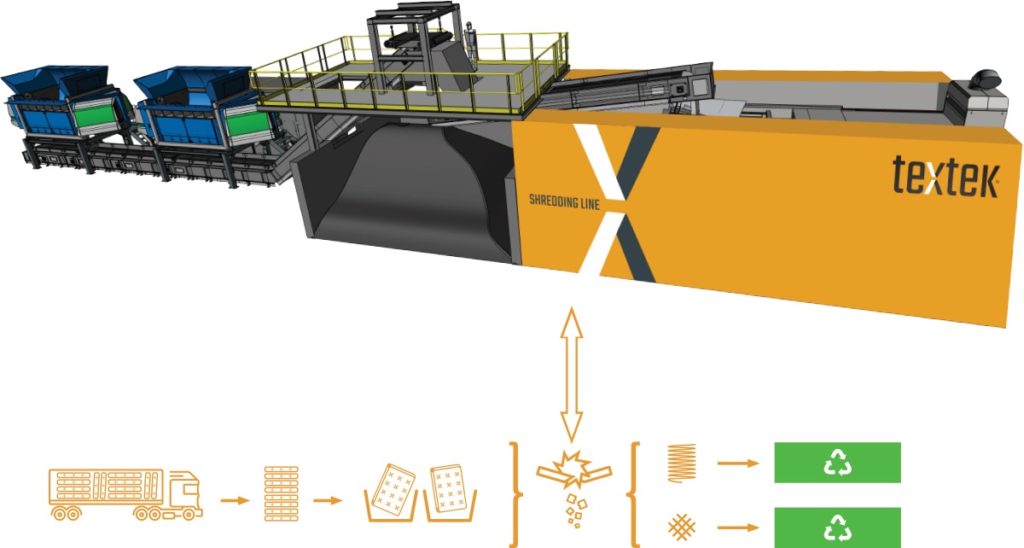

Textek have invested 18 months into the research and development of the first Bespoke Mattress and Bulky Waste Shredding Line, that will divert a staggering one million mattresses a year from landfill.

Its design enables the successful separation of the flock from the steel, ensuring 100% of the mattress can be recycled or recovered.

Textek believe that this line provides a stable future for mattress and other bulky waste recycling and reduces the hard, often dangerous, manual work that is required when stripping a bulky waste product – by hand. On average a skilled person can strip a mattress in around 7 minutes – however the residual products require further processing to enable their reuse.

The Textek Shredding Line is able to dismantle a mattress in under 30 seconds.

We plan to install more Textek plants around the country to help with the on going challenges of mattress, sofa and other bulky waste recycling.

Introducing the UK’s most advanced Bulk Waste Processing Plant.

The solution

Textek has recently invested in a multi-million pound, bespoke Processing Line, which is capable of stripping even the toughest pocket-sprung mattress in less than 30 seconds.

This advanced technology has massively reduced the risks our work-force previously faced on a daily basis, and is a huge step forward in bringing down the number of mattresses destined for landfill.

The steel of the mattress or bulky waste is separated for recycling or recovery, while the remaining elements are blended to create a high calorific value Solid Recovered Fuel (Textek SRF), which is then distributed to create greener energy.

Based in the centre of the UK, Textek is ideally located to source, and store huge volumes of bulky waste. With more than 100,000 sq ft of warehousing, our aim is to take a huge burden off landfill sites, while offering a sustainable, viable solution for Local Authorities and Retailers.

One Textek processing line is capable of stripping over 10,000 mattress a week, diverting vast volumes of bulky waste from landfill, instead converting it into Solid Recovered Fuel.

One Textek shredding line is capable of diverting 1 million mattresses a year from landfill

The benefits

Mattresses may consist of a quilted or similarly fastened case, usually of heavy cloth, that contains hair, straw, cotton, foam rubber, etc., or a framework of metal springs. Stringent fire retardant laws make manufacturers use materials that are a lot safer to use, including:

Metal

Used within the UK and is melted down and turned into many different items from kettles to planes.

Foam

This is broken down and reused as animal bedding and fillers.

Mixed Textile

This is used as a replacement to traditional fossil fuels as a source to power your home.